Related Products

Latest News

Do you know the aluminum radiator processing technology?

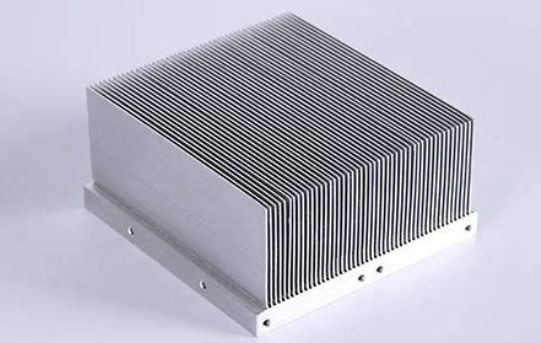

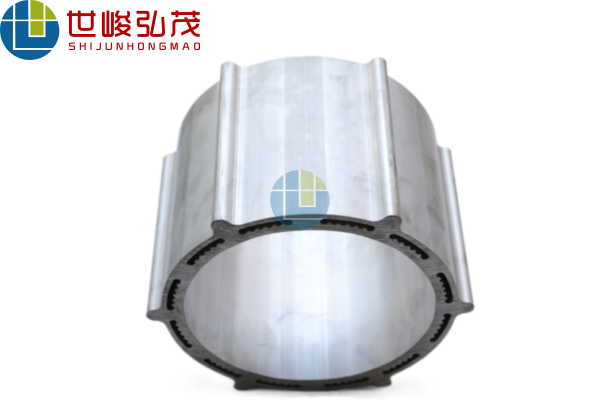

With the development of science and technology and social progress, #aluminum profile radiator, as a kind of efficient and environmentally friendly heat dissipation equipment, has been widely used in various fields. Understanding the processing technology of aluminum profile radiator can help us better understand its design and performance, and also provide reference for enterprises to optimize the production process and improve product quality.

Material selection for aluminum profile radiators is key. Commonly used materials include aluminum alloys and other non-ferrous metals, of which aluminum alloys are widely used because of their light weight, good thermal conductivity and corrosion resistance. When selecting materials, in addition to considering the physical properties and chemical composition, attention should also be paid to the processability of the material to ensure smooth production process.

Processing flow of aluminum profile radiator

1, aluminum profile cutting: according to the design requirements, the aluminum alloy material is cut into the required size and shape. Cutting methods can be flame cutting, laser cutting, etc., of which laser cutting has the advantages of high precision and good kerf quality, but the cost is higher.

2, aluminum bending: the cut aluminum alloy material for bending. The bending process needs to pay attention to control the bending angle and bending radius to ensure that the formed aluminum profile meets the design requirements.

3, aluminum profile drilling: according to the design requirements of the radiator fins, drilling holes in the aluminum profile. The drilling method can be done by drilling machine or laser drilling, in which the laser drilling has the advantages of high precision and good quality of cutting.

4, the production of radiator fins: the aluminum profile after drilling, bending, splicing, made into radiator fins. During the production process, we need to pay attention to the flatness, spacing and height of the fins and other parameters to ensure the heat dissipation effect of the radiator.

5, the assembly of the radiator: the production of good radiator fins and base, side panels, etc. for assembly, the formation of a complete radiator. The assembly process needs to pay attention to the matching precision and connection strength of each component to ensure the stability and service life of the radiator.

Aluminum radiator quality control

In the processing of aluminum radiators, quality control is a crucial link. Quality control includes quality inspection of raw materials, quality monitoring in the production process and quality testing of finished products. Through the establishment of a perfect quality control system, we can ensure that the processing quality of aluminum radiators is stable and reliable. At the same time, for unqualified products for timely treatment and correction, to prevent the problem from expanding.

Aluminum radiator processing process involves multiple links and multiple factors, from material selection to finished product assembly requires strict quality control. Through the continuous improvement of processing technology and the introduction of advanced technology, can improve production efficiency and product quality, but also to meet the market demand for efficient, environmentally friendly heat dissipation equipment. In the future development, the processing technology of aluminum radiator will continue to develop in the direction of high efficiency, automation and intelligence.

Previous: What do you think about the aluminum alloy motor shell process for electric vehicles?

Next: No More