Related Products

Latest News

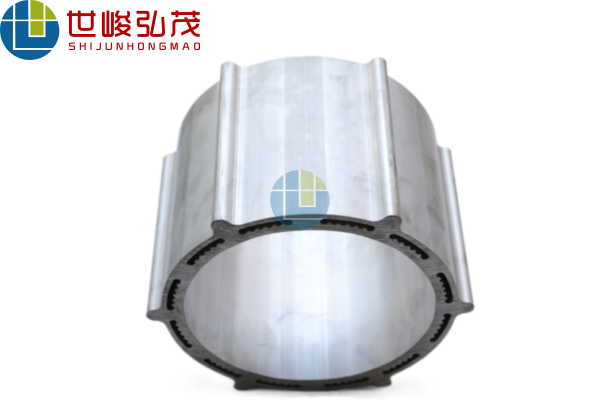

What do you think about the aluminum alloy motor shell process for electric vehicles?

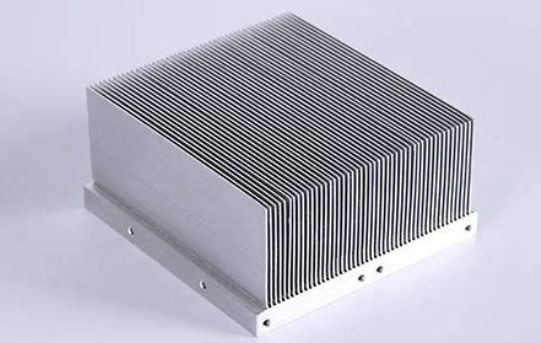

The global energy and environmental crises have prompted the international automobile technology upgrading, which has brought a major strategic opportunity for China's new energy, especially the independent innovation of electric vehicles. Aluminum alloy motor case, as a key component of new energy vehicles, has a complex structure and high performance requirements, Shijun Hongmao Aluminum has taken orders from domestic and foreign motor companies for the production of aluminum alloy motor cases for new energy vehicles.

Hot extruded aluminum alloy motor housing has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, and free cutting of the inner chamber. Aluminum alloy motor casing due to the traditional aluminum alloy motor casing processing process, the case and the end cover of the concentricity is poor, resulting in aluminum alloy casing motor operation noise. According to the machining method of aluminum alloy motor case, a kind of machining tooling for aluminum alloy motor case is designed. Aluminum alloy motor casing using the fixture can achieve a card mounted at the same time after the aluminum alloy motor casing two end stops of the processing, aluminum alloy motor casing bore concentricity of ≤ 0.02mm, improve productivity more than double, to solve the problem of aluminum alloy motor casing motor noise. Aluminum alloy motor casing because of the need for two times in the process of aluminum alloy motor casing clamping, increasing the time of aluminum alloy motor casing processing, thus affecting the production efficiency. Moreover, due to the two times of clamping, the parallelism of the aluminum alloy motor casing cannot be guaranteed, especially the parallelism of the two sections of the aluminum alloy motor casing. In the process of the aluminum alloy motor casing in the use of the motor, due to the difference in the parallelism of the two sections of the aluminum alloy motor casing, it leads to the poor concentricity of the casing and the end cover, which results in the mechanical imbalance of the rotor of the motor of the aluminum alloy motor casing, and it is easy to produce sweeping of the motor, and becomes the aluminum alloy motor casing The main cause of noise generated by the motor, affecting the promotion of aluminum alloy motor shell.

Hot extrusion molding of aluminum alloy motor casing has the advantages of light weight, high strength, good heat dissipation performance, beautiful surface, corrosion resistance, free cutting of the inner chamber. Aluminum alloy motor casing due to the traditional aluminum alloy motor casing processing process, the concentricity of the casing and the end cover is poor, resulting in aluminum alloy casing motor running noise. According to the machining method of aluminum alloy motor case, a kind of machining tooling for aluminum alloy motor case is designed. Aluminum alloy motor casing using this tooling can achieve a card mounted at the same time after the aluminum alloy motor casing two end stops processing, aluminum alloy motor casing bore concentricity of ≤ 0.02mm, improve productivity by more than double, to solve the problem of aluminum alloy motor casing motor noise.

Aluminum alloy motor shell commonly used performance data:

1、 Material grade: 6063-T5

2、 Surface: no treatment, aluminum oxidation, electrolytic coloring

3, the inner diameter work difference: ≤ 0.0007 D; roundness ≤ 0.0012 D

Shijun Hongmao Aluminum's other aluminum alloy motor shells are also used for: micro motor shells, environmental protection air conditioning motor shells, chiller motor shells, water-cooled air conditioning motor shells, air compressor motor shells, negative pressure fan, motor shells, motor shells, motor shells of electric vehicles, tricycle motor shells, servo motor shells, injection molding machine motors, cooling tower motors, cylinder barrels, axial fan motors, power tool motors, speed reducers, and other aluminum alloy motor shells. fan motors, power tool motors, gear motors and so on.

Welcome to communicate and discuss with us, our engineers will also assist you in evaluating the drawing