Related Products

Latest News

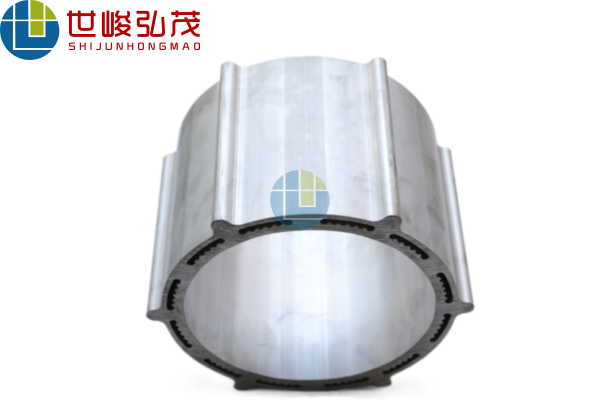

The CNC Aluminum Processing Services

Aluminum is A Commercial Metal

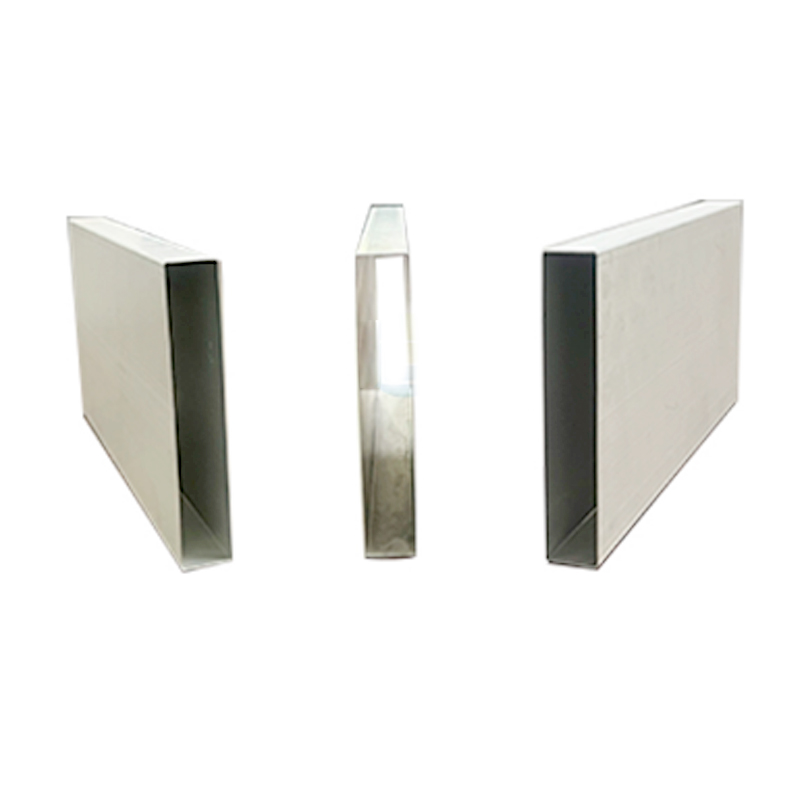

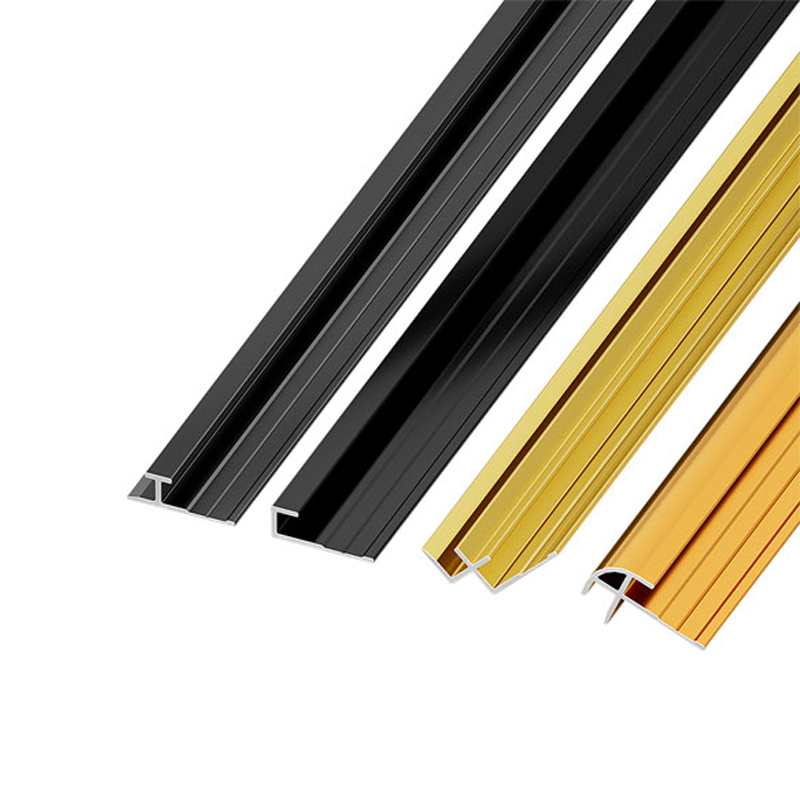

Aluminum CNC machining is a common practice in manufacturing industries. Aluminum is a soft metal that is extremely malleable and lightweight. The alloying elements that make aluminum stronger and harder provide it with many benefits. Standard aluminum is ninety-nine percent aluminum. The remaining one percent is comprised of manganese, copper, and zinc. This makes aluminum a very versatile material. The benefits of CNC aluminum machining are many.

For precision aluminum machining, a variety of tools and processes are available. aluminum CNC machining tools typically feature a higher helix angle than standard end mills. Using specialized cutting tools that have a higher helix angle can reduce chatter while maximizing material removal. Other important factors to consider when aluminum machining is the clearance angle and helix angle. When the clearance angle is too low or too high, the tool will dig into the work and cause friction.

Aluminum is a durable and lightweight material. Its lightweight properties make it a popular commercial metal for a variety of applications, including aircraft parts. It is also highly resistant to corrosion and a good reflector of light. As a result, it is often used in lighting equipment. It is also a good absorber of shock and is useful for aircraft, ships, and boats. CNC aluminum product processing can help ensure that your parts are made to the highest quality and performance.

Benefits of Aluminum CNC Machining

There are several benefits to CNC machining aluminum services. The material is highly machinable, light, and corrosion-resistant. However, there are many factors to consider when choosing an aluminum CNC machine. Listed below are some of the factors to consider before choosing a CNC aluminum machine. When choosing a CNC machine, the tool to use depends on several factors, such as tool speed, the size of the workpiece, and the type of workpiece to be made.

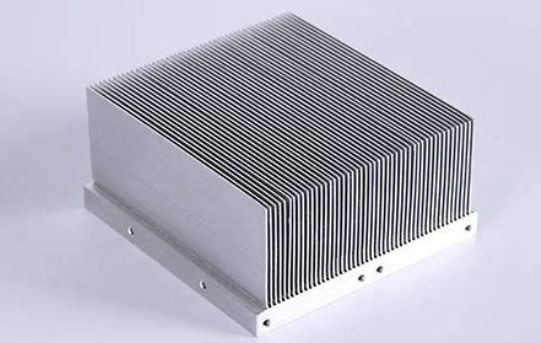

Highly Machinable

Aluminum is a highly machinable metal, but the process is highly competitive. The alloy is highly machinable, but can also deform under high forces. The recommended speed and feed for aluminum machining are determined by the grade of the aluminum being machined. Aluminum machining feeds should be at least 0.020 inches in all areas. The right machined tool for aluminum can drastically increase shop efficiency. The material is readily formed and machinable. It is lightweight and requires very little power for machining. Its machinability is another major advantage of CNC aluminum machining. It can be machined to tight tolerances and has a high degree of accuracy, which reduces labor costs. CNC aluminum machining is highly machinable. CNC aluminum machining processes are second only to steel in the frequency of execution.