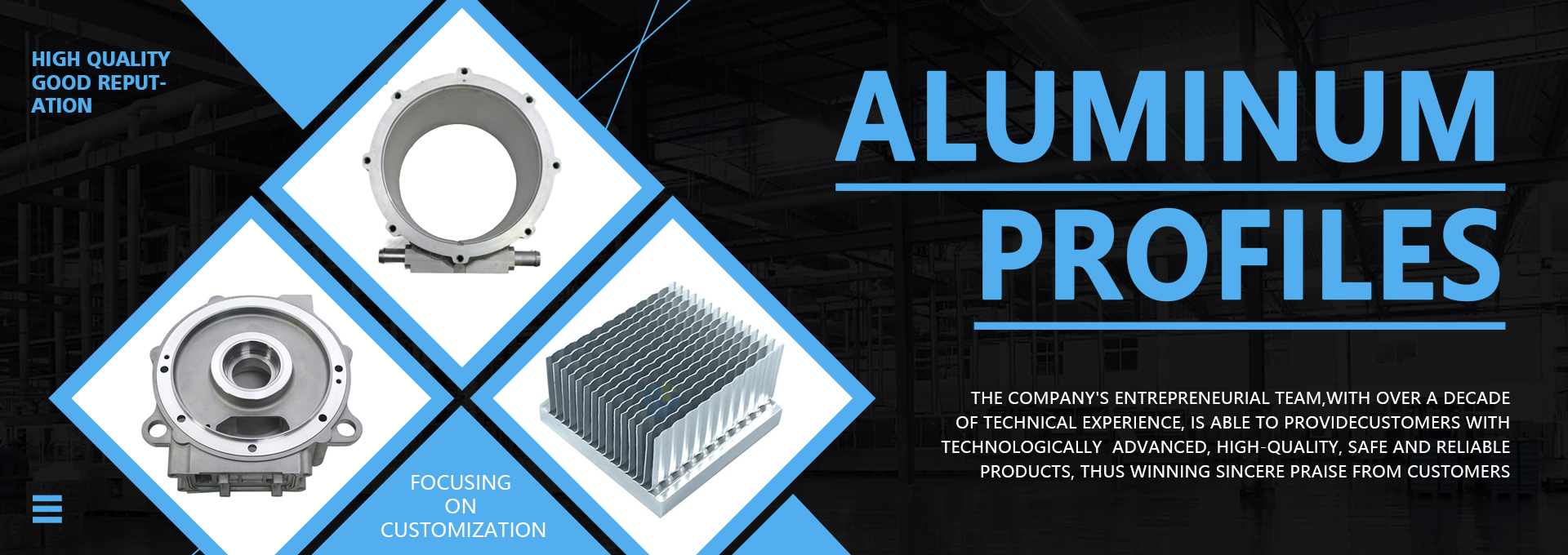

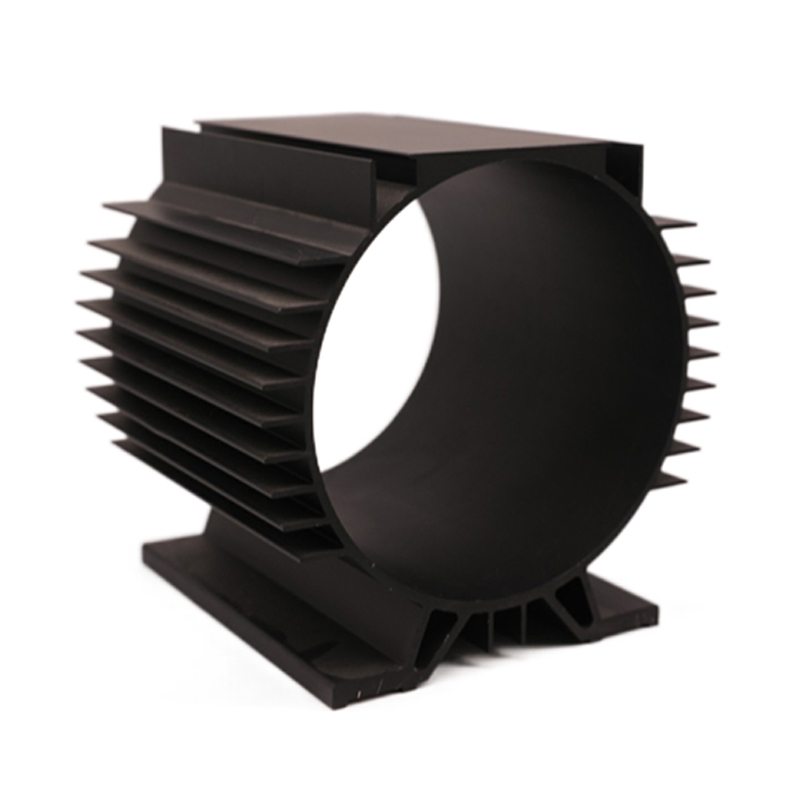

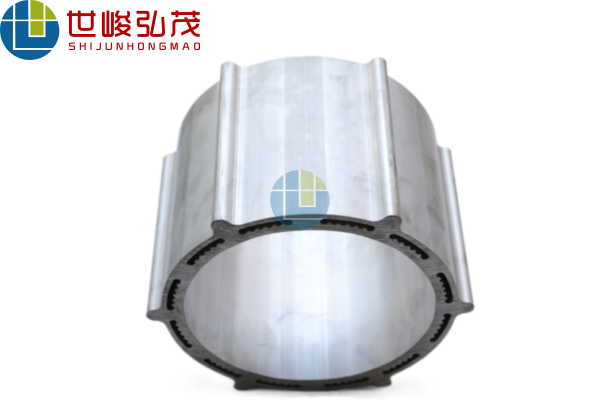

New Energy Vehicle Motor Aluminum Alloy Shell

Specifications

ITEM: New energy vehicle motor aluminum alloy shell

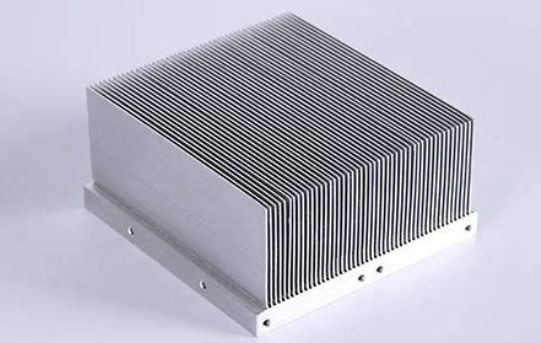

Product Material: National standard 6063-T5 high-purity aluminum alloy

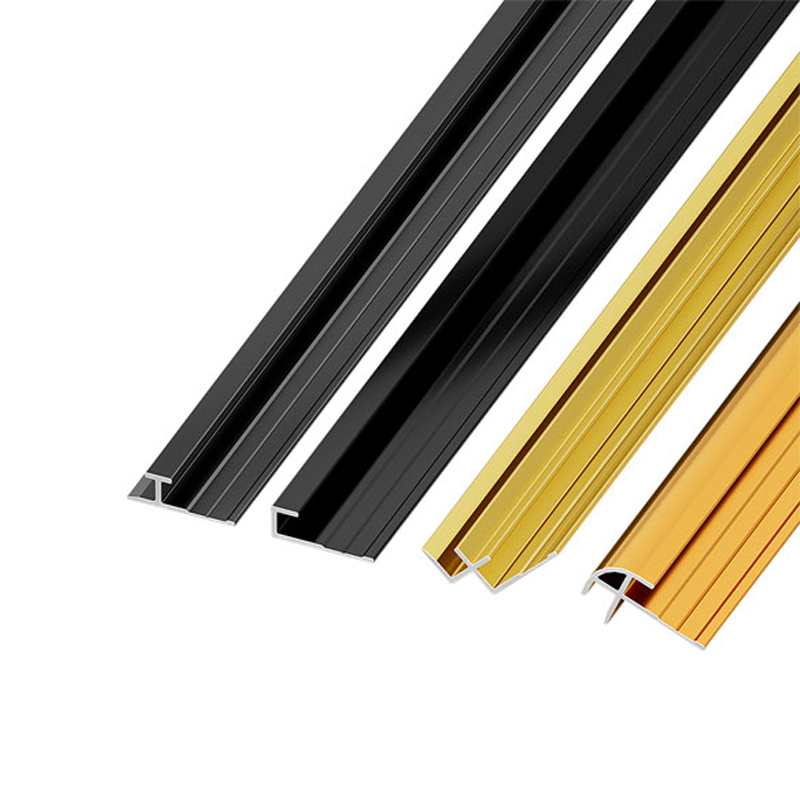

Surface Treatment: Mill finish, anodizing, electrophoresis, powder coating, wooden color, fluorocarbon coating, polished, brushed, etc.

Coating Film Thickness: 8~25um for anodizing film, 40~120um for powder coating film

Product structure design: Adopting European and American industrial aluminum profile design standards, light weight and high-end appearance.

Product safety standards: Using high-strength aluminum alloy extruded profiles, the national wind tunnel test can withstand 14 typhoons

Product life: The use of high-quality surface treatment and high-quality aluminum alloy materials can extend the service life

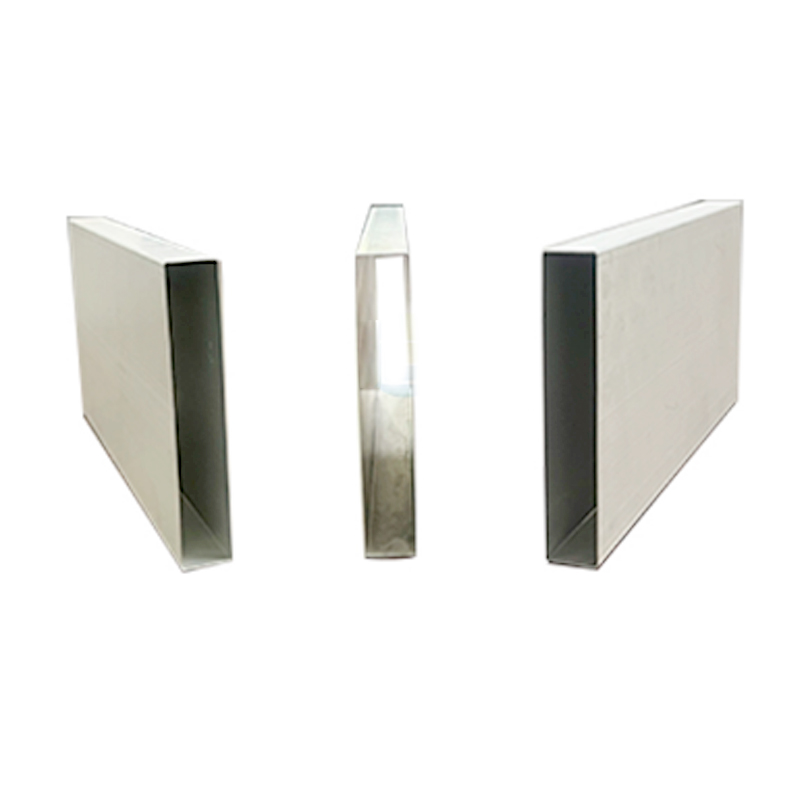

Packing Details:

Inside: Packed with protection film to protect the surface of each profile

Outside: Wrapped with hot shrink film and waterproof craft paper

Delivery Time: Die Tooling & Sample Testing: 7-15 days;

Mass Production Completed: 15~25 days after samples are confirmed by the buyer

FOB Port: Guangzhou / Shenzhen / Foshan

Payment Term: T/T 30% for deposit and 70% for balance before shipping

Guarantee: Surface finish can be stable for 10~20 years for indoor usages

Product application: Highway street lights, urban main roads, community roads, community parks, stadiums

Characteristic Custom Produce: 16 years of experience in custom development and production of aluminum profiles, support custom development and production

Shipping Method: Ocean shipment, air shipment, land transportation and multi-transportation, etc.